In 2014, Dunlop Systems and Components relocated from a leaky old factory in Holbrook to a highly efficient new factory in 2014. At the same time the company fundamentally redesigned the high pressure steam processes used in making its air suspension components, saving the business 67 per cent on energy and 38 per cent on water use. This strategic approach to resource efficiency turned around a failing company to become a thriving domestic and export business providing high quality jobs in Coventry.

In 2014, Dunlop Systems and Components relocated from a leaky old factory in Holbrook to a highly efficient new factory in 2014. At the same time the company fundamentally redesigned the high pressure steam processes used in making its air suspension components, saving the business 67 per cent on energy and 38 per cent on water use. This strategic approach to resource efficiency turned around a failing company to become a thriving domestic and export business providing high quality jobs in Coventry.

Is this an example of what all UK manufacturing businesses will look like in 2050? Highly skilled workers using technology to optimise how resources flow through clean, hyper-efficient factories. With those factories generating their own energy as well as using it. It’s a great vision and achieving it would help boost productivity and close the gap between the north and south.

But the answer to the question is not the emphatic yes it should be. These improvements will only be made by those companies that happen to understand the importance of resource efficiency to their bottom line. This is unless, of course, the government’s new industrial strategy takes an active role in supporting more small and medium sized manufacturers to achieve a turnaround like Dunlop.

The message from our recent report, Lean and clean: building manufacturing excellence in the UK, is that a manufacturing upgrade programme to encourage and reward more resource efficient production should be right at the heart of the industrial strategy. And we aren’t the only ones to think so. This message has been supported by business leaders and representatives, including the British Chamber of Commerce, the TUC and the North West Business Leaders Team.

Why a focus on manufacturing is needed to rebalance and decarbonise the economy

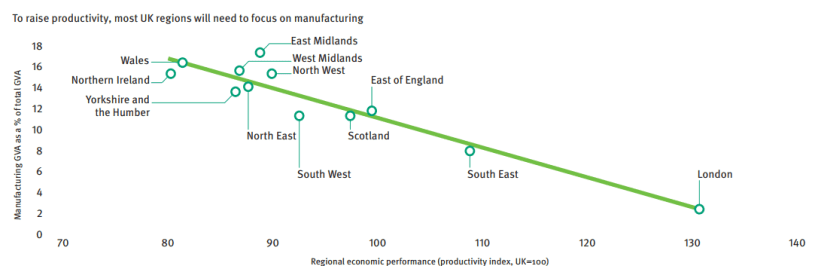

It is no secret that the UK economy needs rebalancing. London and the South East are way ahead of other UK regions on productivity. And, interestingly, those regions where productivity is low are those with the largest share of manufacturing businesses.

Manufacturing, however, is not the cause of low productivity and could be part of the solution. In the past ten years, the UK’s top performing manufacturers have improved their energy efficiency by 50 per cent, but most have achieved only ten to 15 per cent, so there is huge potential for improvement.

Apart from the obvious benefit of reducing business costs, improving resource efficiency will also help the economy to decarbonise, as manufacturing is responsible for a fifth of the UK’s carbon emissions.

UK manufacturers, as net material importers, have been particularly exposed to volatile and rising material costs in the global market. Prices of resource inputs have increased by 75 per cent in the past 15 years, compared to wages, which have risen by just eight per cent in the same period. Last year alone, the fall in sterling pushed crude oil prices up 56 per cent and the cost of metals up by a third.

If businesses fail under these pressures, manufacturing jobs will leave the UK for countries with lower labour costs and less ambitious decarbonisation targets damaging our economy and doing nothing to reduce global emissions.

Government manufacturing support programme is needed

There are three reasons why companies won’t necessarily adopt more resource efficient processes by themselves.

First, market prices do not fully reflect the environmental costs of extraction, resource depletion and waste. Larger and more sophisticated companies build carbon and resource pricing into their decision making but most companies don’t have enough understanding of their exposure to future resource constraints and price shocks. .

Second, companies also struggle to identify and quantify the inefficiencies and vulnerabilities in their operations, which leads to underinvestment in the technology that could deliver product and process solutions.

Third, businesses rarely include energy and resource efficiency in their strategic foresight and planning. They see efficiency as an incremental rather than strategic and potentially transformational part of their operations.

As Steve Evans at the Institute for Manufacturing, University of Cambridge has said: “The government’s industrial strategy should provide foresight and benchmarking for UK manufacturers to realise the untapped potential of resource efficiency and help build long term manufacturing competitiveness.”

We propose the following five step manufacturing upgrade programme to overcome the market failures:

The government is looking for ways to address falling productivity and rebalance the economy, as Brexit raises the stakes for UK manufacturers competing globally. It has also committed to decarbonising the economy. Upgrading to lean, clean manufacturing is the obvious way to do it.

The government is looking for ways to address falling productivity and rebalance the economy, as Brexit raises the stakes for UK manufacturers competing globally. It has also committed to decarbonising the economy. Upgrading to lean, clean manufacturing is the obvious way to do it.

Angela is speaking at the Battle of Ideas on 28 October 2017.